REMET CNC Technology

REMET CNC TECHNOLOGY has been operating on the market of precision metal machining and machine production since 1998.

Many years of experience have facilitated the proper identification of the market and the needs of customers in the field of wood processing.

Our qualified personnel and specialised machine park work hard to produce high-quality devices tailored to the expectations of all users (two series of chippers: STANDARD and PROFESSIONAL). Continuous development of the company, employee training, quality control, implementation of the latest manufacturing technologies (laser cutting, machining of chipper elements on precision CNC machining units) results in the fact that our machines are always of the highest quality.

The wood chippers and splitters that we manufacture are recognised both on the domestic market in Poland and around the world.

We welcome you to get to know our product range, and visit our YouTube channel and Facebook profile where we constantly post information about current promotions and videos from the work of a wood chipper.

Have you got any questions? Call us! Our consultants will gladly provide with all the information and help to choose a wood chipper that matches your expectations.

Our team

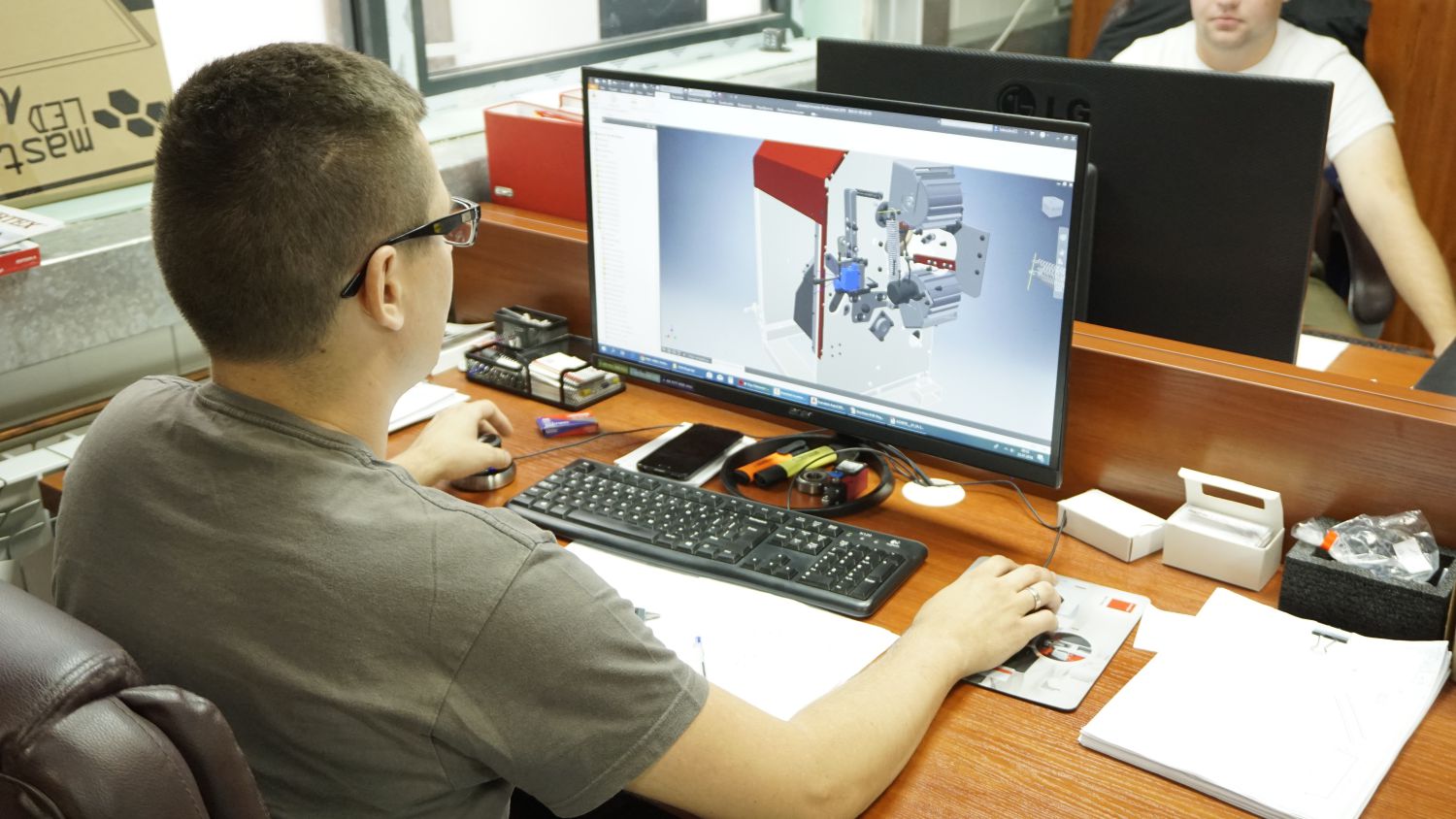

The REMET CNC TECHNOLOGY team consists of over 80 employees, gradually growing as a result of the continuous development of the company and production growth. The core of the team is a young but experienced design and technology department that ensures that our shredders, chippers and wood splitters are always of the highest quality and meet the expectations of our customers, while at the same time maintaining maximum safety.

The design and technology department is divided into:

- Designers-constructors who develop new and develop existing wood chippers and log splitters,

- Technologist-programmers who care for the correct and efficient course of the technological and production process.

- Quality controllers whose task is to verify the production process, control of manufactured components, ready machines and close cooperation with designers and technologists.

The production team is composed of:

- a harmonious team of CNC numerical machine tools operators,

- laser and plasma cutters,

- hardeners, welders, turners, locksmiths.

The production workers constitute the largest part of the entire team.

The assembly department gathers mechanics, technicians, assemblers and electricians who, from the manufactured elements and components, assemble and mount wood chippers and splitters offered by REMET CNC TECHNOLOGY.

The ready devices go to the warehouse and shipping department where they are stored and sent to recipients.

The last department is the trade and information department, which provides comprehensive services to a rapidly growing group of individual customers and distributors not only in Poland, but also in Europe, North America and Asia.

Machine park

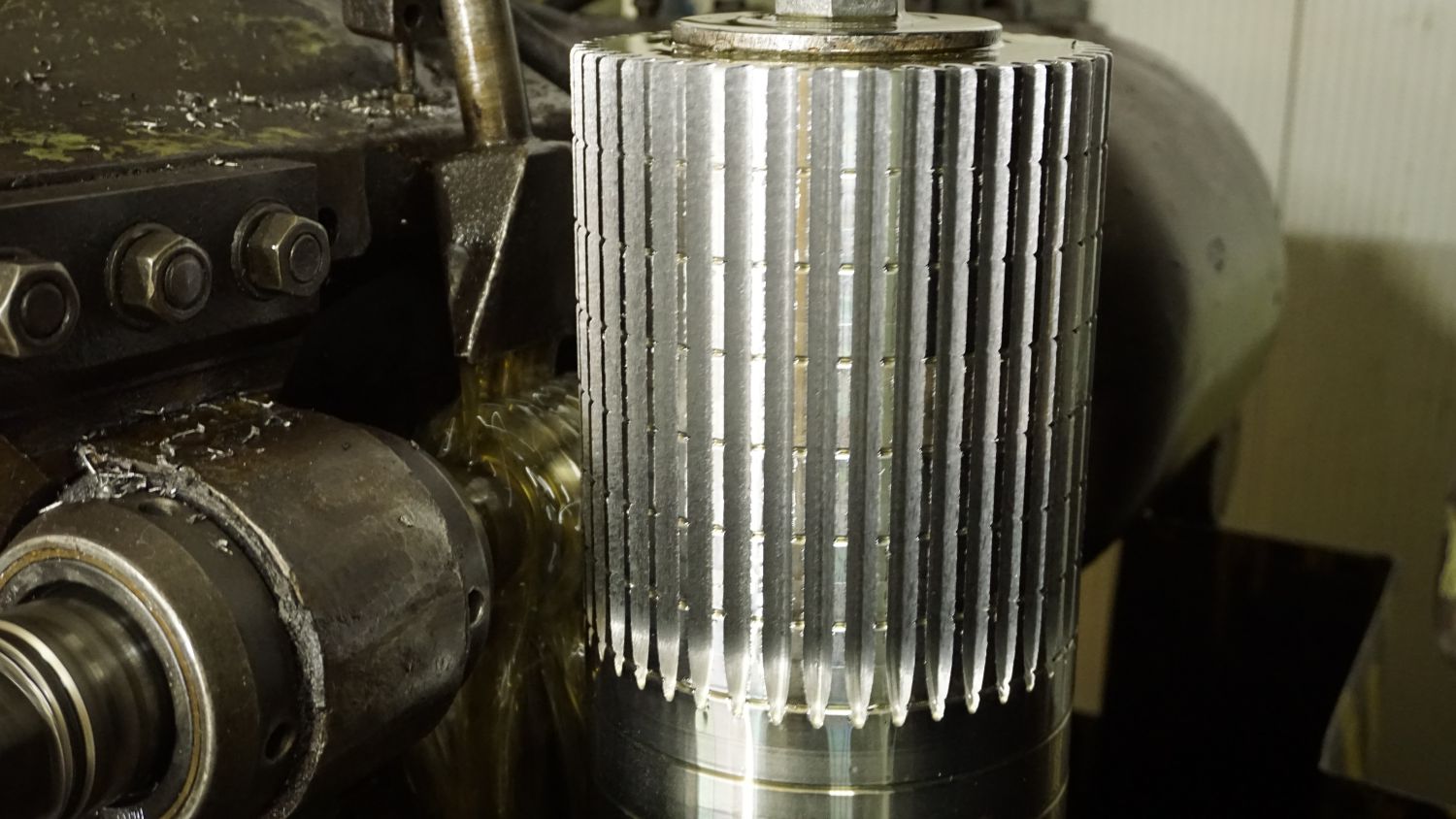

Our plant is equipped with modern CNC machines. The machine park is supplemented with a number of conventional devices, which facilitates comprehensive customer service in the field of metal processing. The machine park is constantly being developed with the most modern machines and technologies.

A BYSTRONIC FIBRE 6kW laser cutting machine:

- Table loading area 1,500 x 3,000 mm, max. cutting thickness up to 25 mm

Two DURMA hydraulic presses:

- AD-S 2060, pressure 60 tons, bending length 2,050 mm

- AD-S 2060, pressure 175 tons, bending length 3,050 mm

Vertical machining units, CNC DOOSAN models:

- Two DNM 500 II CNC units , shift (X / Y / Z) 1,020/540/510 mm,

Table loading area 1,200 x 540 mm - Four DNM 650 II CNC units, shift (X/Y/Z) 1,270/670/625 mm,

Table loading area 1,300 x 670 mm

Horizontal AFM machining units models:

- One CMC DOOSAN PUMA GT 2,600 unit

- Four CNC TAE 30N2 units, max. part weight in the holder: 150 kg,

ø330 length 500/1,000 mm - Three TAE 45N2 CNC units, max. part weight in the holder: 150 kg,

ø390 length 500/1,000 mm

Ten welding stations:

- Welding with TIG MIG MAG methods

- Powder painting shop

- Factory surface: 4,000 m2

The company operates in a two-shift mode.

BySprint Fiber 3015 6kW Laser Processing Unit

High performance and the highest quality of sheet metal cutting in the format of 3 to 1.5 m. Additional functions (Power Cut Fibre, Cut Control Fibre, nozzle change system, Detection Eye) and automation options maximise the spectrum of applications. High flexibility. The ability to process non-ferrous metals while maintaining excellent quality.

| Scope of machining | mm |

|---|---|

| sheet nominal dimension | 3000×1500 |

| max. speed of simultaneous positioning | 140mm/min |

| By Vision: operation via touch screen and manual control unit |

CNC Vertical Machining Unit by Doosan DNM650 (2 pcs)

The device enables fast and precise execution of complicated elements using many tools. The machine can use many tools during one cycle, automatically fed to the spindle, depending on the needs, e.g., drilling, milling, threading or reaming. The control of the machine is entrusted to CNC control systems, which is the most efficient control system used in machining.

| Scope of machining | mm |

|---|---|

| Axial shift X | 1270 |

| Axial shift Y | 670 |

| Axial shift Z | 625 |

REMET CNC TECHNOLOGY M&P Piekut Sp. k.

is a modern and dynamically developing family business, specialising in professional machining of metals and plastics on CNC machine tools.

We welcome you to get to know our product range, and visit our YouTube channel and Facebook profile where we constantly post information about current promotions and videos from the work of a wood chipper.

in Poland

in Poland

in Germany

in Germany

in the Czech Republic

in the Czech Republic